| View previous topic :: View next topic |

| Author |

Message |

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Sun Jul 15, 2012 8:03 pm Post subject: Posted: Sun Jul 15, 2012 8:03 pm Post subject: |

|

|

My son used the pressure washer to clean off the transmission out of the yellow donor. Here is a shot of the right side:

The left side:

I am not sure if the numbers are significant, but I thought I'd post them for completeness:

It does look like either the bell housing was clearanced, or somehow the clutch or ring gear rubbed on it. Maybe these marks are normal?

The starter seems unremarkable. I guess we will rebuild one and have two for spares:

Last edited by Baxsie on Fri Aug 08, 2014 12:33 pm; edited 1 time in total |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Wed Jul 18, 2012 10:06 pm Post subject: Last of the Yeller 1974, probably Posted: Wed Jul 18, 2012 10:06 pm Post subject: Last of the Yeller 1974, probably |

|

|

We are continuing to take the yeller bug apart. This is partially to let the boy learn about wrench-turning, but also so both of us can have a good understanding of how these beasts are put together.

I do not think that the chassis is worth saving. There horrible rust on the right side foam area. Pretty bad rust on the left side foam. Bad body repair on the front. Some rust in the passenger side lower front just in front of the door post. Battery rust. I am not going to cut it up just yet, but at this point I do not think there is much to use.

Our next step is to separate the body from the pan so we have some experience with that process on a car that we can mess up without consequence.

In any case, we pressure washed the yeller bug after he removed the interior and we got most of the wiring out.

Things I learned:

* there is an access hole at the bottom of the door pillar that lets you make sure the defroster hose is connected

* there is foam in the seam above the parcel area. I had not heard about that.

* the "tarboard" under the front seats has a thin layer of the white styrofoam . . . it seems like I knew that at one time, but I had forgot.

* apparently there is no way to remove the hard plastic heater tubes that are bolted through the body under the back seat

* the wiring harness is foamed in at the right rear

So here are pictures, just for reference:

In these two images, you can see that a good portion of the front was replaced . . . and the seam is with spot brazing (?):

OK, just for fun and learning.

Last edited by Baxsie on Fri Aug 08, 2014 12:37 pm; edited 2 times in total |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Thu Jul 19, 2012 9:15 pm Post subject: Posted: Thu Jul 19, 2012 9:15 pm Post subject: |

|

|

We received and inspected the absolutely incredibly complete front door seal kit from West Coast Metric:

https://shop.westcoastmetric.com/viewProduct.php?productID=113-0669

Painfully expensive, but seems to have EVERYTHING and it all seems to be very good quality and packed very well. No shipping damage at all.

It even has the little buttons that go in the top of the hinges, and the clear plugs that cover the hinge screws.

It will be awesome to have the doors seal perfectly! |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Sat Jul 21, 2012 4:31 am Post subject: Posted: Sat Jul 21, 2012 4:31 am Post subject: |

|

|

We got the chassis separated from the pan, well for the most part:

I could not disassemble this ball-joint. I'll have to research what it takes to separate those.

Last edited by Baxsie on Fri Aug 08, 2014 12:37 pm; edited 1 time in total |

|

| Back to top |

|

|

ONEBADBUG

Joined: 25 Oct 2003

Posts: 440

Location: Spokane

|

Posted: Sat Jul 21, 2012 4:05 pm Post subject: Posted: Sat Jul 21, 2012 4:05 pm Post subject: |

|

|

| You just need a "pickle fork". |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Sun Jul 22, 2012 9:02 am Post subject: Posted: Sun Jul 22, 2012 9:02 am Post subject: |

|

|

| ONEBADBUG wrote: | | You just need a "pickle fork". |

I saw those. Someone said that they damage the boot? Well, in any case I ordered a puller set, and a front-end service set:

http://www.amazon.com/gp/product/B000NPUKB6

http://www.amazon.com/gp/product/B0002SRH7O

Complete overkill for this job, but I need a set of pullers for general use anyway, and I need to replace all the ball joints in the front end of my tractor. Plus, I am a tool slut  |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Wed Aug 08, 2012 2:25 pm Post subject: Posted: Wed Aug 08, 2012 2:25 pm Post subject: |

|

|

This is only peripherally connected to the bug project, but through several happenstance events, I now have what have to be the absolutely coolest shop lights ever, two full-size real-medical-hospital-surgery lights:

I plan to set them up over a bay where the engine stand and engine work will happen. I can do "surgery" on the motor.

How does this kind of stuff happen?

Last edited by Baxsie on Fri Aug 08, 2014 12:38 pm; edited 1 time in total |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Wed Aug 08, 2012 2:25 pm Post subject: Posted: Wed Aug 08, 2012 2:25 pm Post subject: |

|

|

My CAD guy had some time to work on the 3d model for the Honda mirror mount:

Still some work to do, but at this point I think it is very possible to make the mount fit right over the VW factory mounting hole and use that hole for mechanical mounting.

That is a 3d-print in PLA by a MakerGear Mosaic printer:

For the real one, we will mill (or have milled) one out of aluminum, or maybe have Shapeways print one out of Stainless Steel.

Last edited by Baxsie on Fri Aug 08, 2014 12:39 pm; edited 1 time in total |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Tue Sep 11, 2012 9:04 pm Post subject: Posted: Tue Sep 11, 2012 9:04 pm Post subject: |

|

|

Finally finishing up on the "get ready for winter" chores.

My son put the yeller '74 body back down on the yeller '74 chassis so we could push it out of the barn. That disassembly has added some well-earned "wrench time" to his resume, and a much better understanding of the bug construction for both of us.

He is now feeling pretty confident about taking a bug apart, so he is starting on the disassembly of the White 1975 LaGrande Super Beetle:

We are pretty sure that this is a green "LaGrande" bug.

This is the base chassis and body that we hope to use for the build. It gives us:

1) rack-and-pinion steering

2) fuel injection tank, and two hard lines from the tank to the engine

3) sunroof

Last edited by Baxsie on Fri Aug 08, 2014 12:39 pm; edited 2 times in total |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Sun Sep 30, 2012 8:28 am Post subject: Posted: Sun Sep 30, 2012 8:28 am Post subject: |

|

|

My son has been working hard on stripping all the parts off the White 1975 LaGrande Super Beetle. It is now showing a lot of its original green (compare to the pic in this post):

The weather here has been a bit of an atypical hot dry fall. Many years by now it would be much cooler and rainy. We took advantage of the good weather to do a full, hard pressure wash of the body and pan:

Here is a quick photo tour of the bug, still wet after washing.

Driver side:

Front:

Passenger Side:

Rear:

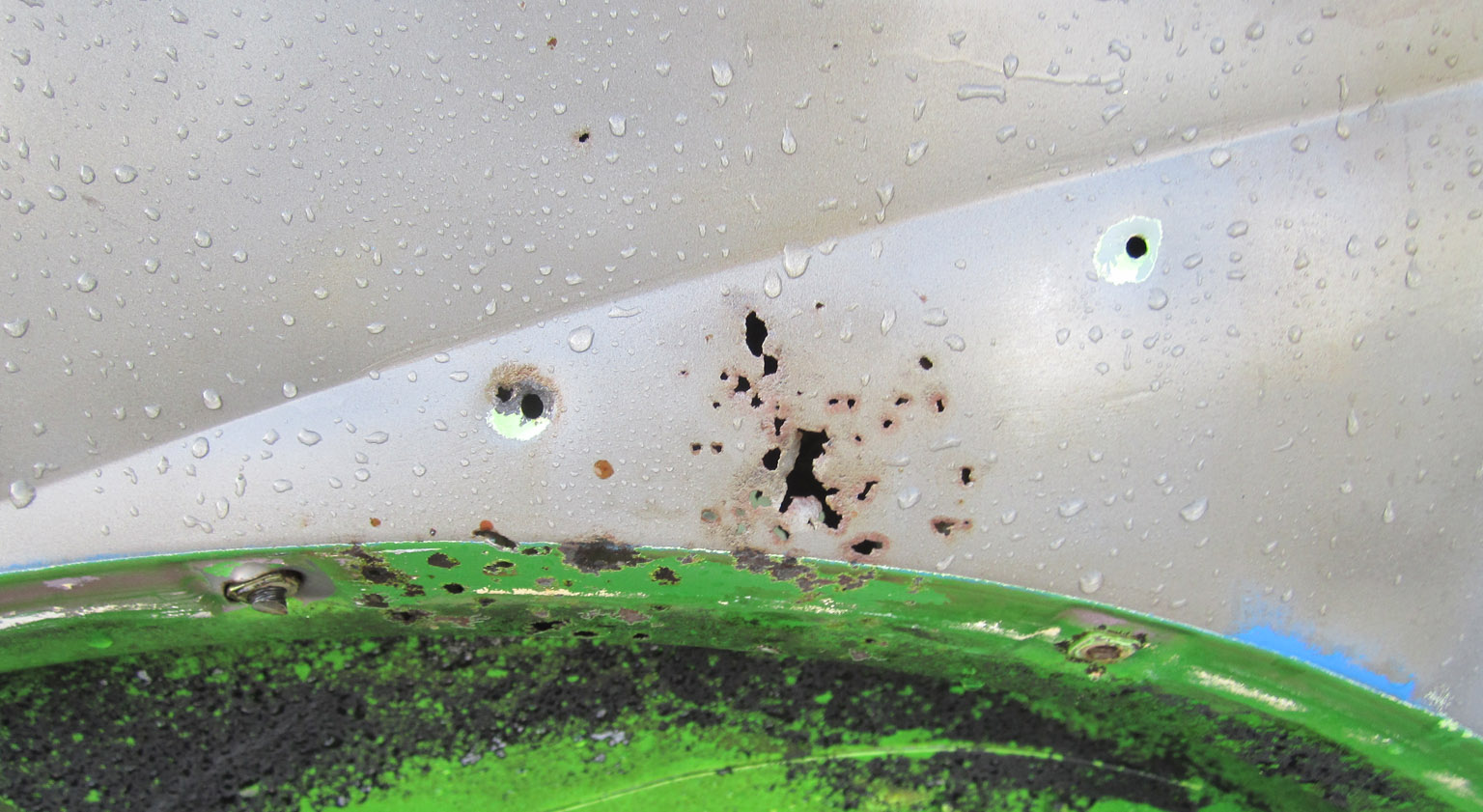

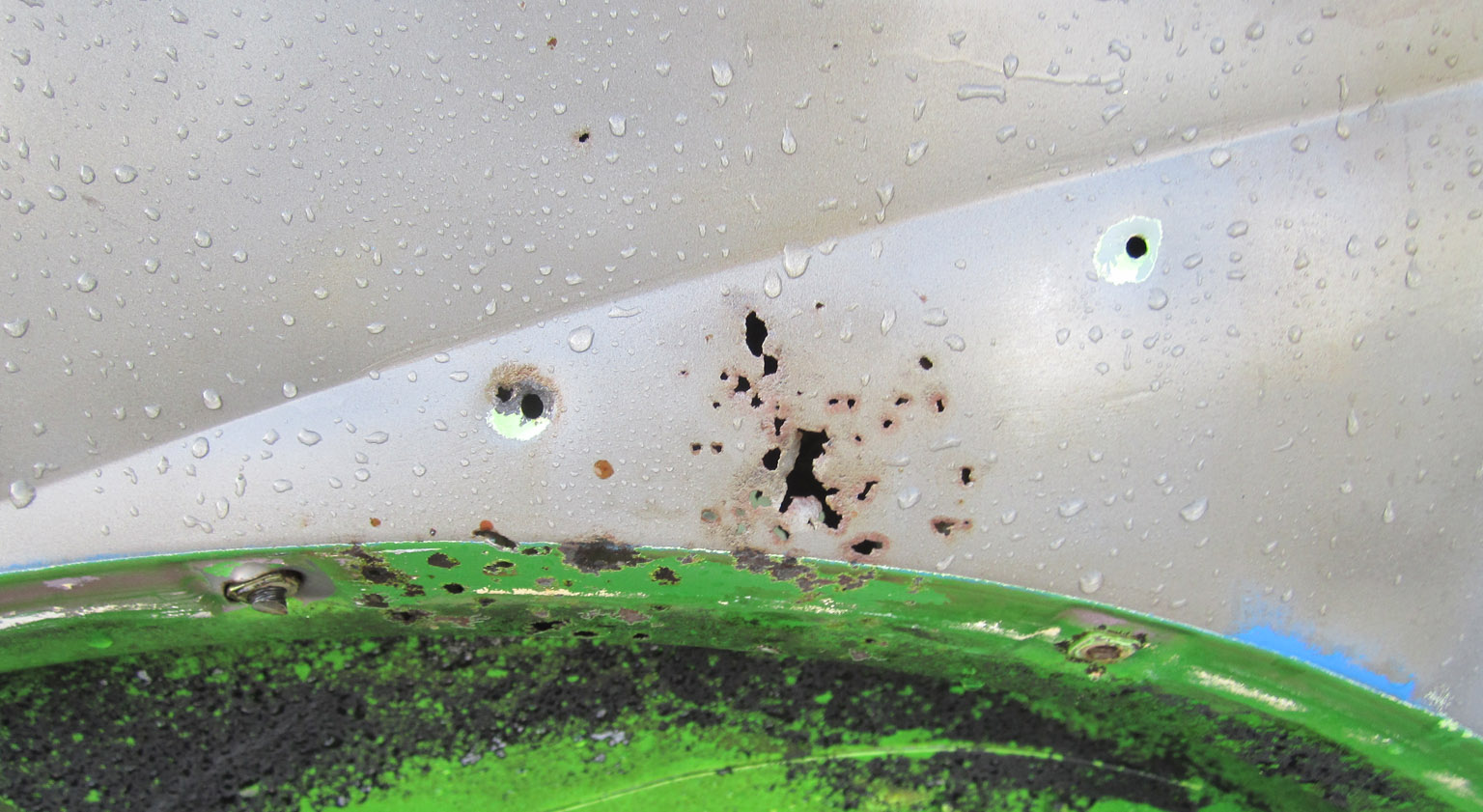

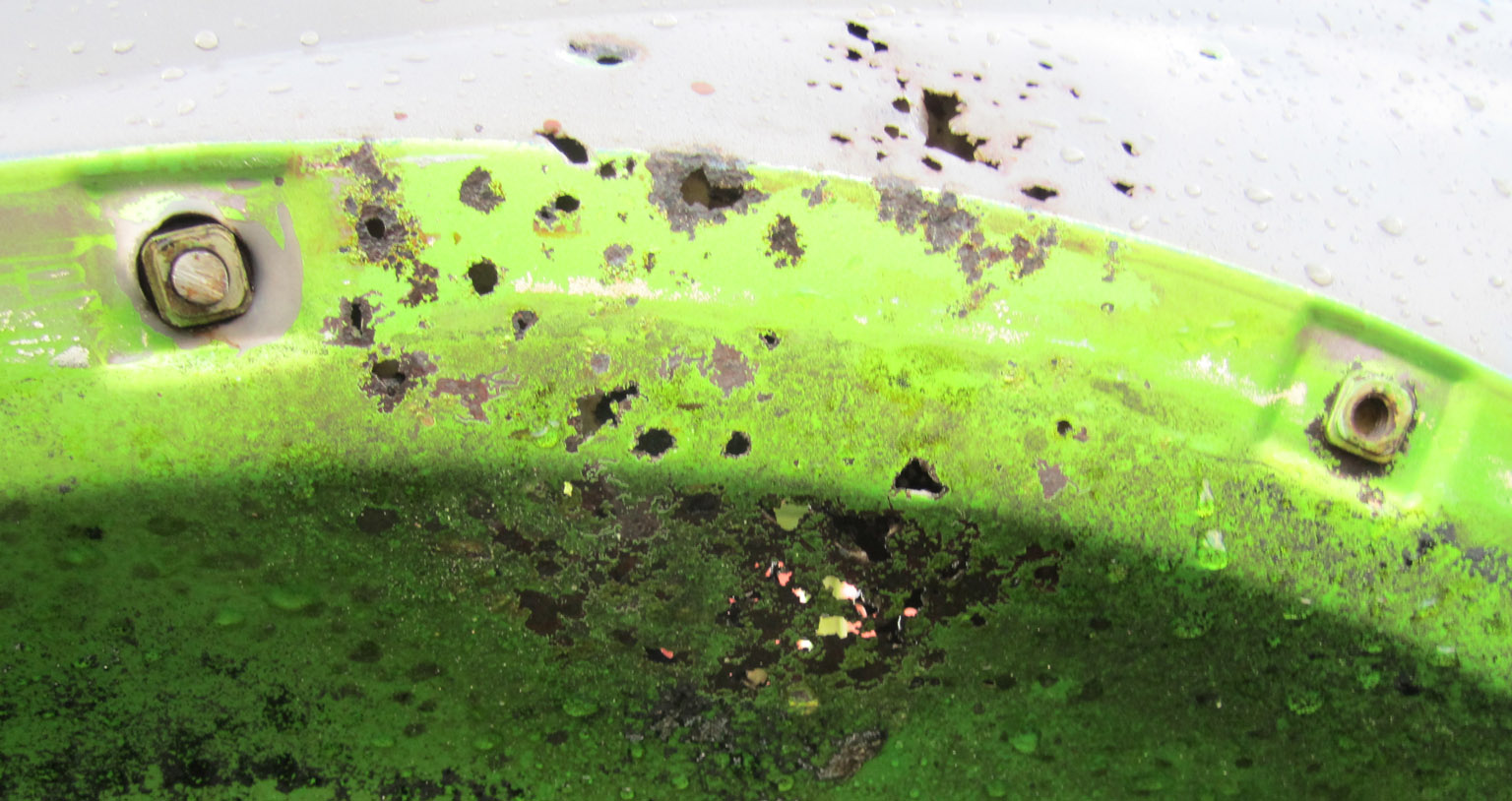

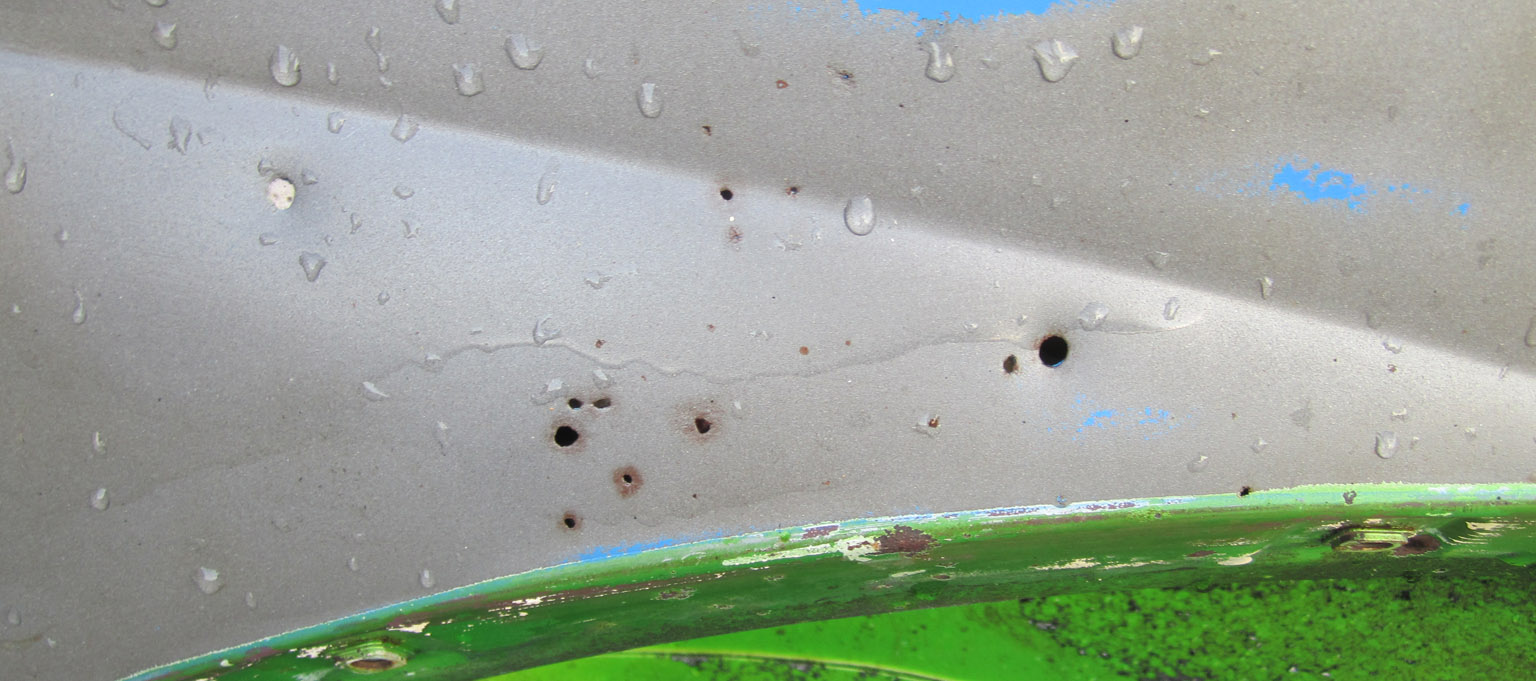

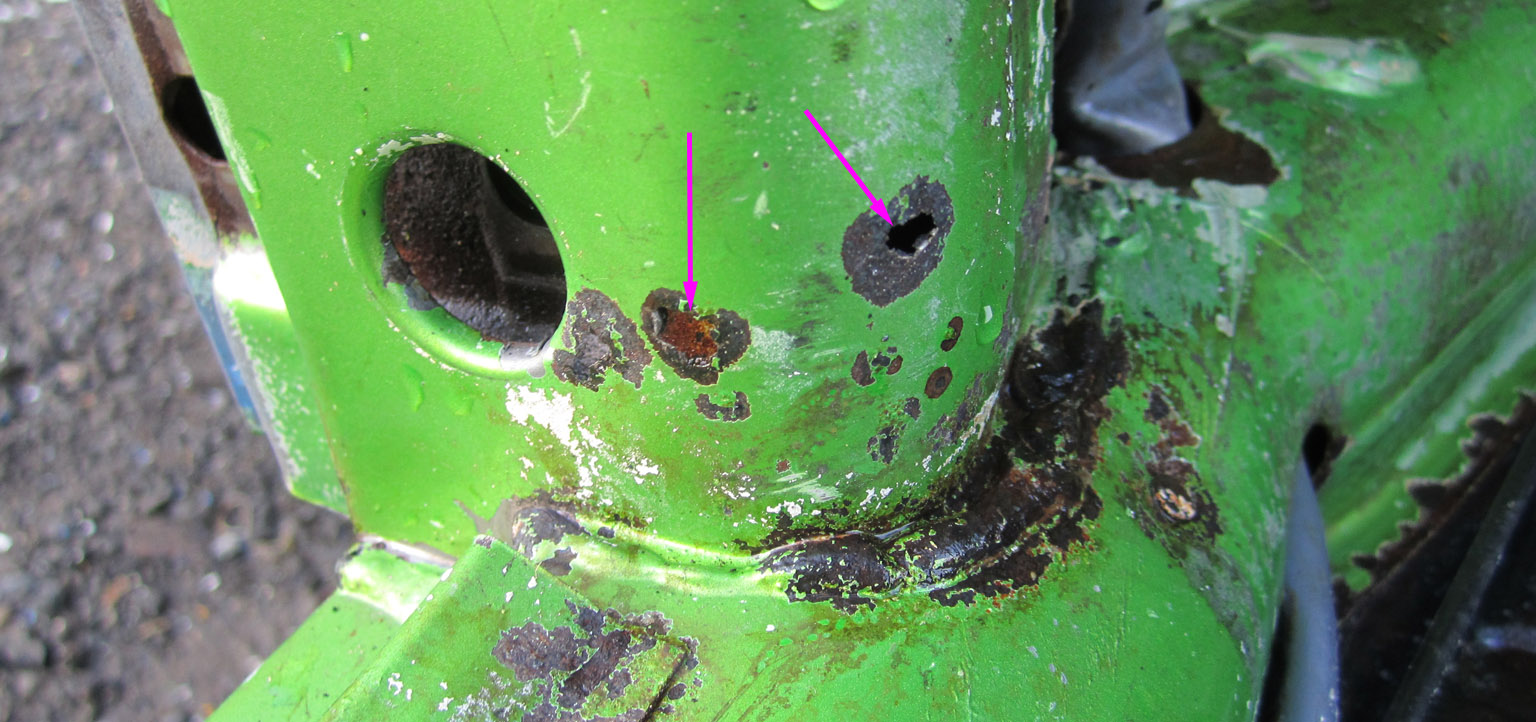

Detail of "foam of death" rust above right rear wheel well:

That rust extends down into the wheel well also:

Interior view of the same rust area:

Here is the "foam of death" area above the left rear wheel well:

There is also a perforation by the back window, near the lower edge on the driver side:

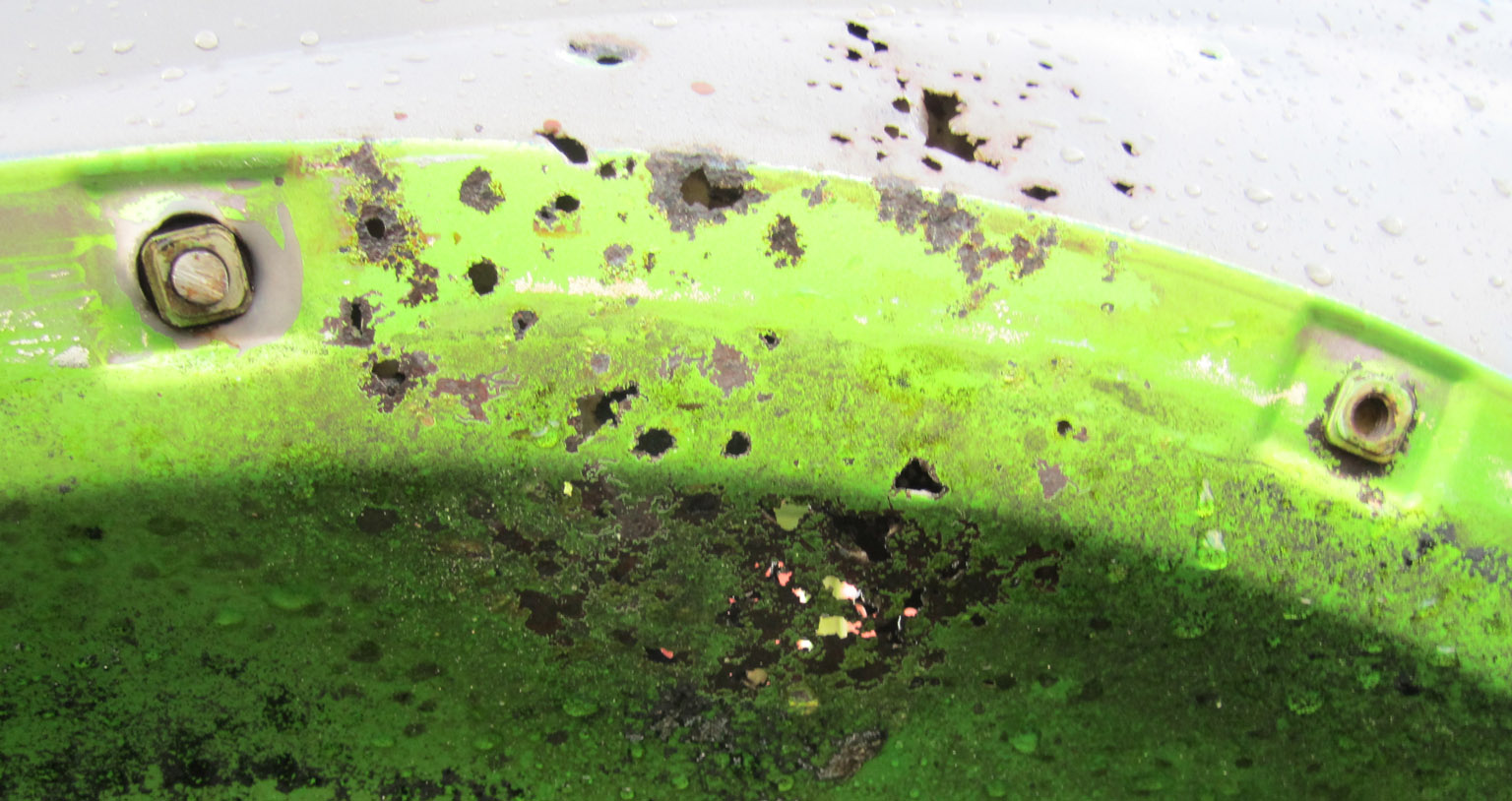

The right pan is a complete mess. The battery box is rusted out, as you would expect:

There is a hole near the outer seat track:

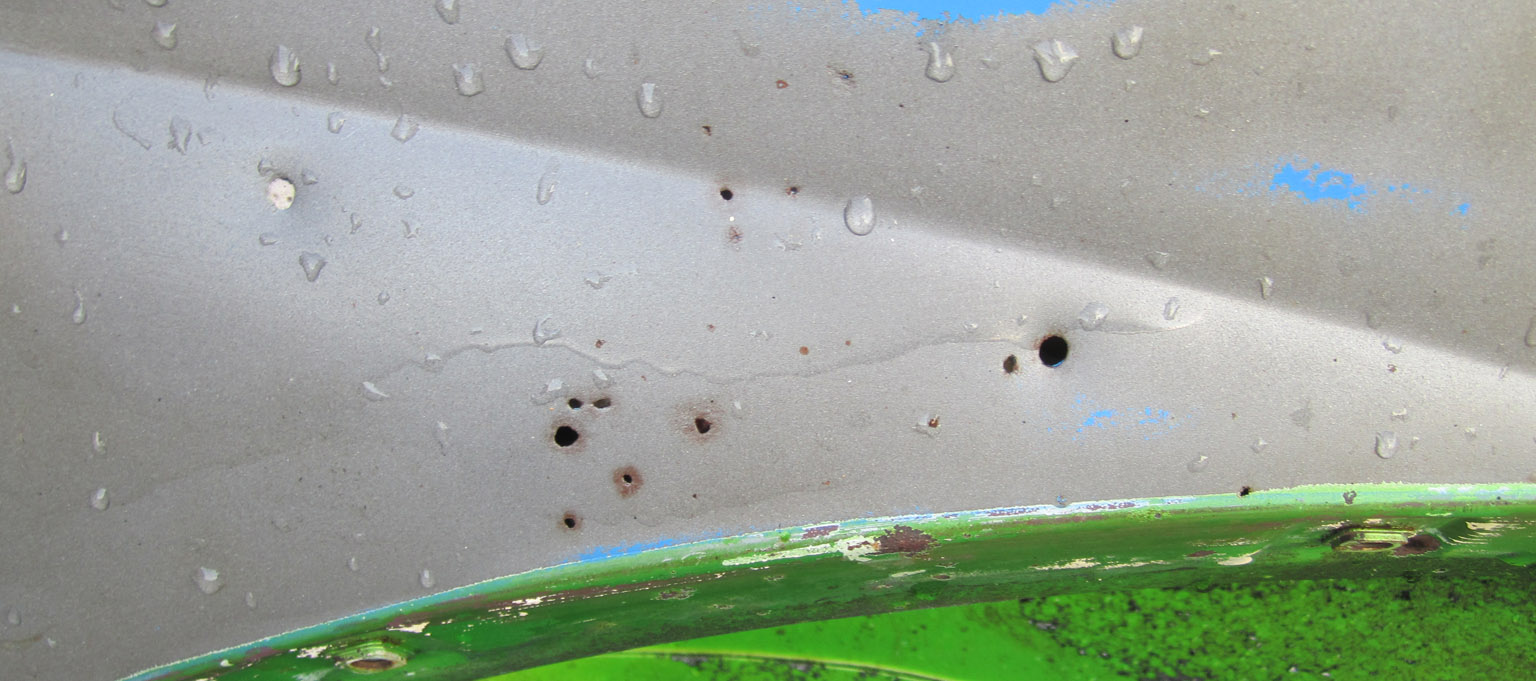

Up in the passenger footwell area, the rust is rampent, many small perforations:

There is a good size hole near the inner edge of the passenger seat pylon:

In contrast, the driver side pan is near perfect:

Here is a shot of the luggage tray. The car had been re-upholstered. There was foam attached using spray adhesive, and under that area there was surface rust:

Here is a shot of the sunroof tray. I am a little surprised by how thick it is--that is how far it extends down into the passenger compartment:

The drain that empties the fresh air box was rusted out, and there is a second rust area there a bit to the left:

Here is a shot of the fresh air box from the front, rust indicated:

There is some surface (not all the way through) rust in the windows channels. Left rear quarter:

Windshield:

The channels around the sunroof will also need some rust removal/reprime:

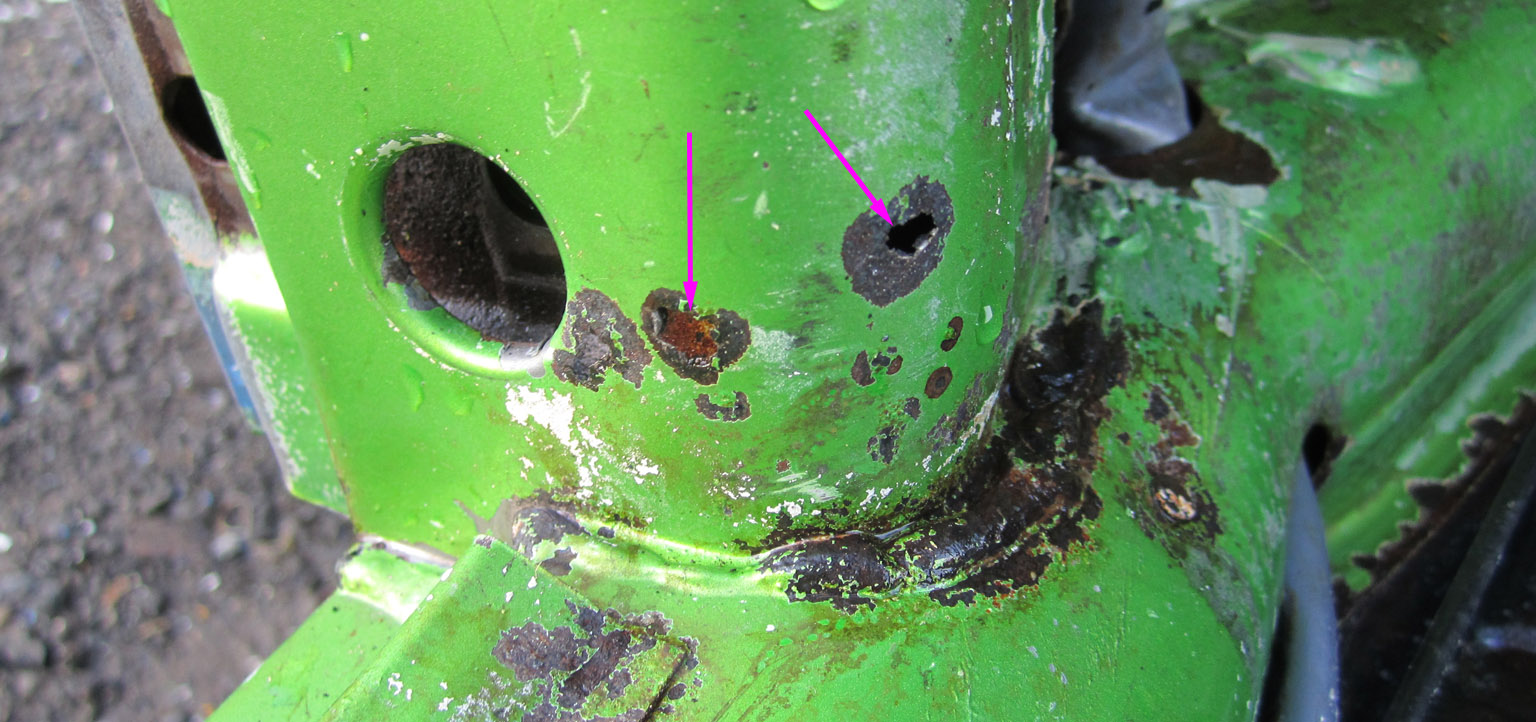

The driver's door pillar has some perforated rust. We also ended up drilling out the bottom hinge bolt on both sides. We will have to deal with that at at some point:

Here is a walk around the car. Passenger side rear wheel well. You can see the foam of death holes:

Some blown fender mounting holes to fix:

Right rear bumper mount:

Engine compartment, right side:

Engine compartment, left side:

Left rear bumper mount:

Driver side rear wheel well:

Drivers side front wheel well:

Passenger side front wheel well:

Looking closer into the drivers side front wheel well, you can see a pretty crappy repair of the front apron. They did not remove the old apron, and the new apron is not lined up very well. I have a new front apron and spare wheel tray, so this will get repaired. I needed to replace the front apron with one that was vented, since behind the vent is where one of the the A/C condensor goes:

More blown fender mounting holes, and some impact damage to fix:

Inside the trunk on the driver side, the PO has made the fender nuts by brazing them in place:

Here is a shot inside the trunk showing the the left side repair of some front impact. We have a new spare wheel well so this should all go away:

Right side impact repair:

Looking at the repair from the outside, in front of the passenger side front tire, you can again see that the original apron was not removed. There is also some kind of nasty weld or cutting torch slice:

There was some hole patched with palstic near the fuel filler. The pressure washer excels at discovering this kind of stuff:

Last edited by Baxsie on Fri Aug 08, 2014 12:39 pm; edited 2 times in total |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Sun Sep 30, 2012 4:28 pm Post subject: Posted: Sun Sep 30, 2012 4:28 pm Post subject: |

|

|

Another beautiful fall day here. The boy got the pan and body separated this morning:

We then tilted it up so we could give the underside a good scrubbing. Having the pans backlit REALLY shows how the passenger pan is COMPLETELY shot, while the driver pan has only one small hole:

Next we lifted up the body so we could get all the underside bits clean:

The fuel pump had been hanging from the hose in front under the front of the car. Now that it is all clean, you can clearly see the rubber mounting that the fuel pump was intended to be mounted to:

Last edited by Baxsie on Fri Aug 08, 2014 12:41 pm; edited 1 time in total |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Tue Oct 02, 2012 6:17 am Post subject: Posted: Tue Oct 02, 2012 6:17 am Post subject: |

|

|

For the fenders and running boards, here is the approach I am currently thinking of:* pressure wash the dirt and loose paint off

* bead blast down to the bare metal

* have them dipped in zinc chromate (thread here)

* have the body shop prep/prime/paint as normal

* undercoat the bulk of the fender

* truck bed liner sprayed in the area behind the wheel that tends to get hammered by gravel We got all the ICEAC parts today. We did a quick "hold it in place" look at how the evaporator mounts. I am not sure that it will not take up an uncomfortable amount of the footwell space. I almost want to take it apart and see if I could jam all the components into the center console area . . . maybe start with something like this:

ref: http://www2.cip1.com/ProductDetails.asp?ProductCode=ACC-C10-3494-11

We would have to look at airflow, the size of the evaporator, source for fans, whether to make ducts. Bleh.

We were trying to decide where to cut to get access to the foam of death area. I think we are going to have to go back to Nepenthe88's foam article to revise this first doodle:

When we pressure washed, we hit this area hard and long. It will be interesting to see how much of the foam was removed.

For kicks we looked at one of the many rear window actuators that I have collected from Pull-and-Save:

Interesting . . . especially since that area has to be gone into for the foam rust issue anyway.

My son got the rack-and-pinion out:

That is on the list of things that need to be done: clean, check, new boot, re-grease.

Well, there is still lots to do  most of my time is still going into working on the shop insulation so we can get the heater installed for the upcoming long winter nights. most of my time is still going into working on the shop insulation so we can get the heater installed for the upcoming long winter nights.

Last edited by Baxsie on Fri Aug 08, 2014 12:41 pm; edited 2 times in total |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Sun Oct 07, 2012 7:45 pm Post subject: Posted: Sun Oct 07, 2012 7:45 pm Post subject: |

|

|

We took some time off to make the Farm Boy Chassis Rotisserie.

He is back on the chassis disassembly, but now with the chassis at a nice work height

Last edited by Baxsie on Fri Aug 08, 2014 12:42 pm; edited 1 time in total |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Tue Oct 09, 2012 11:11 am Post subject: Posted: Tue Oct 09, 2012 11:11 am Post subject: |

|

|

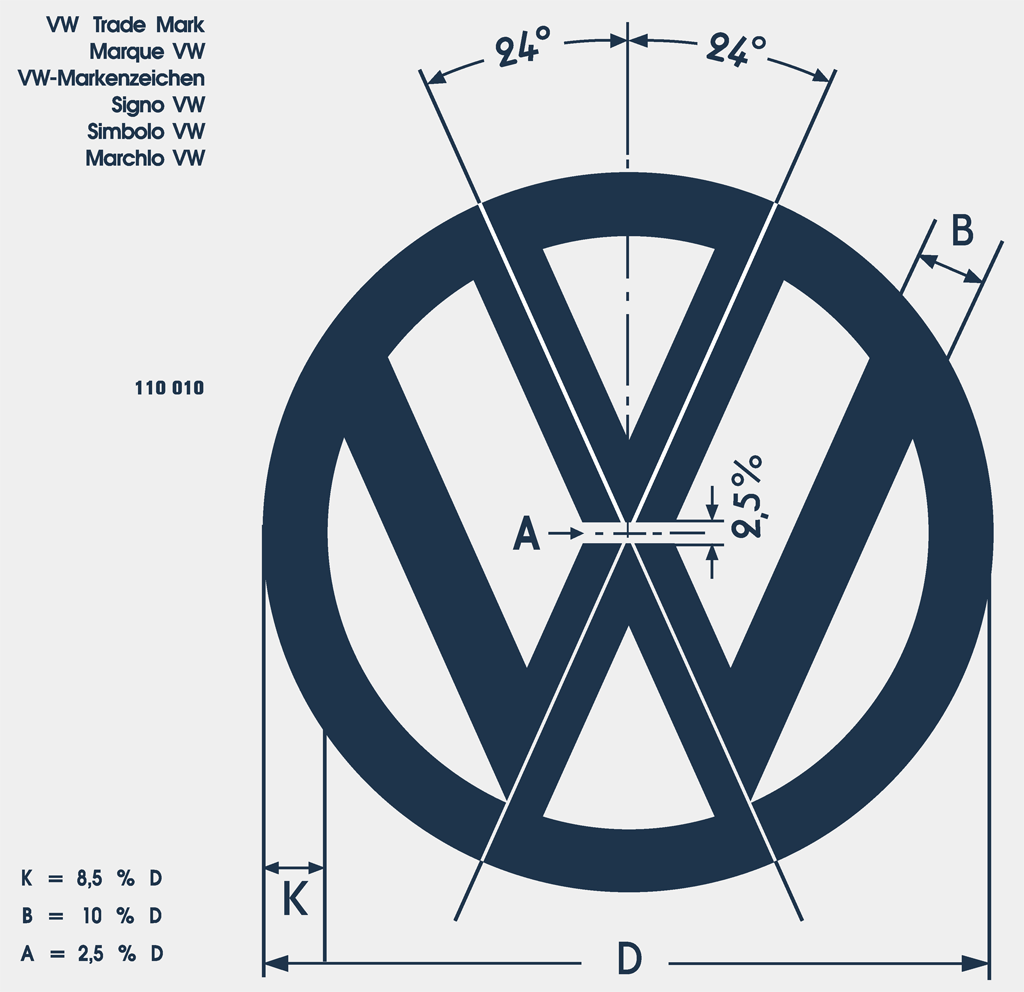

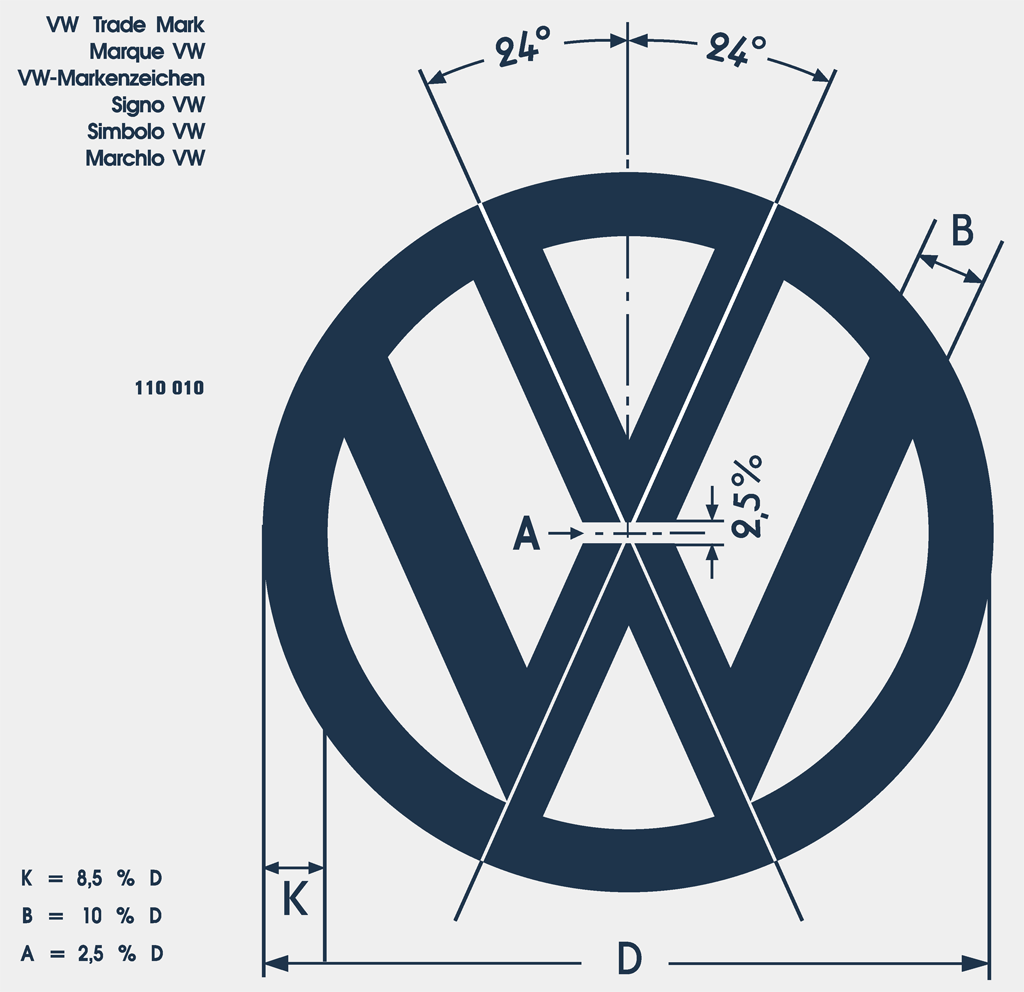

My CAD guy took some time to make a preliminary design for a VW logo center cap for the Porsche Boxster wheels. This first model is printed on our MakerGear Mosaic in silver PLA.

We probably mill the final parts out of aluminum.

We know the logo is perfect, thanks to this awesome drawing:

That image comes from this way-cool blog post:

http://imjustcreative.com/recreated-vintage-vw-logo-specification-sheet/2011/08/03/

There is something to be said of the Volkswagen philosophy when the entire logo can be dimensioned by using only four numbers.

Last edited by Baxsie on Fri Aug 08, 2014 12:42 pm; edited 1 time in total |

|

| Back to top |

|

|

Baxsie

Joined: 12 Apr 2012

Posts: 253

|

Posted: Tue Oct 16, 2012 7:24 pm Post subject: Posted: Tue Oct 16, 2012 7:24 pm Post subject: |

|

|

My son has been working on getting the chassis stripped, it is looking pretty naked:

Today he took on removing the floor pan. He only got about half way before we had to break for dinner. Tomorrow it should be out.

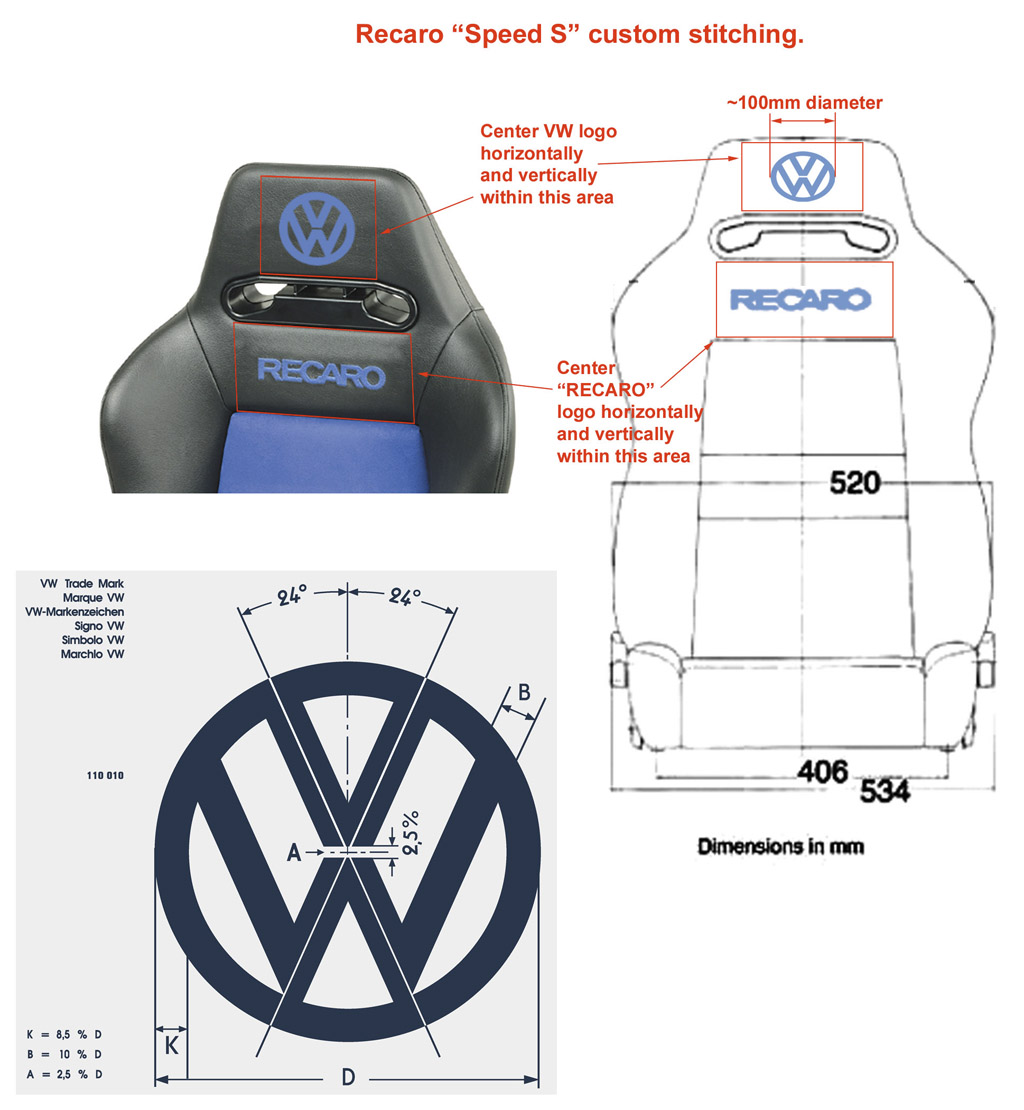

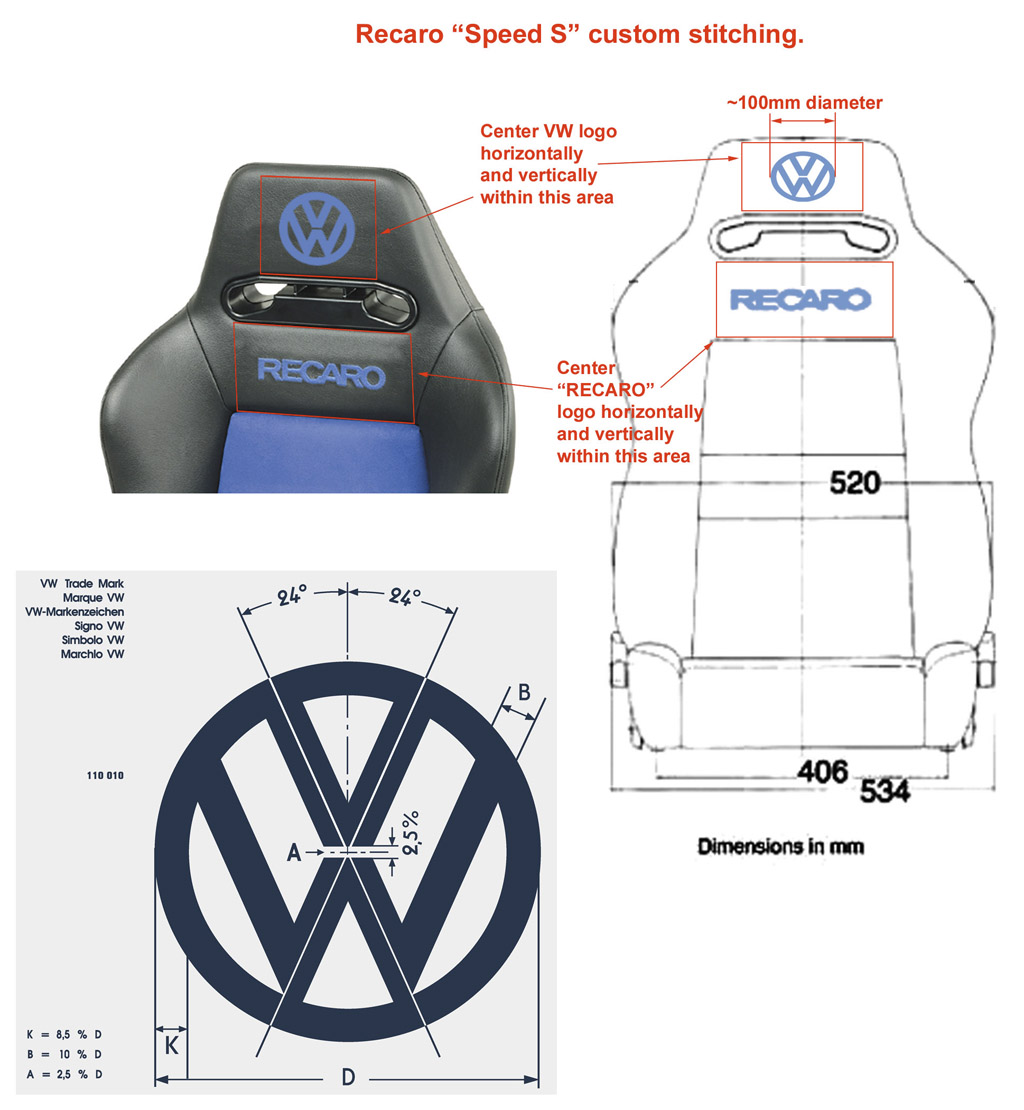

He also removed the seat tracks and pylon off the new pan. The plan is to install some aftermarket seats to custom cross-members that tie into the roll cage. Here is the concept for the seats:

Hopefully those seats work out.

Last edited by Baxsie on Fri Aug 08, 2014 12:43 pm; edited 1 time in total |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

|